86-0755-23089386

6th Floor, Building B5, Zone A, Fuhai Industrial Park, Fuhai Street, Baoan District, Shenzhen, Shenzhen, Guangdong, China

| Quantity(Units) | 1 - 10 | >10 |

| Est. Time(days) | 12 | To be negotiated |

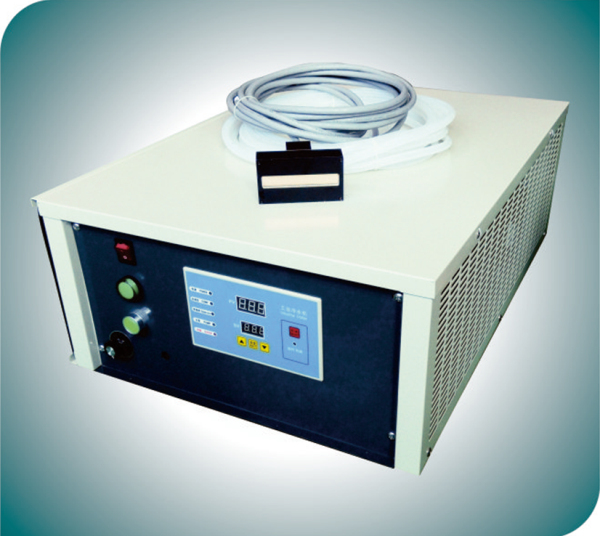

| UV LED curing system's specification | |

| Controller size | 350*300*230mm |

| LED size | 48.5*22.5*31mm |

| UV Emitting window sizes | 35mm*14mm |

| LED QTY | 2 pcs |

| Wavelength | 365-405 nm |

| Intensity | above 8w/cm2 |

| LED Voltage | 24V |

| Cooled method | Water cooled |

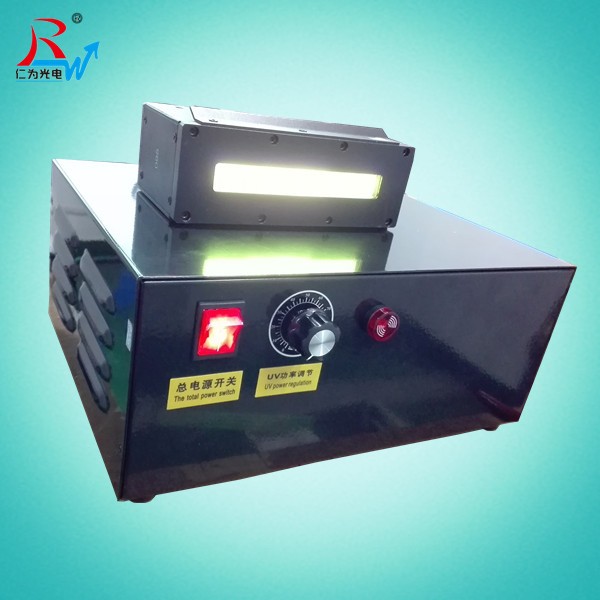

| LED UV curing machine's specification | |

| Controller size | 350*300*230mm |

| LED size | 48.5*22.5*31mm |

| UV Emitting window sizes | 35mm*14mm |

| LED QTY | 1 pcs |

| Wavelength | 365-405 nm |

| Intensity | above 8w/cm2 |

| LED Voltage | 24V |

| Cooled method | Water cooled |

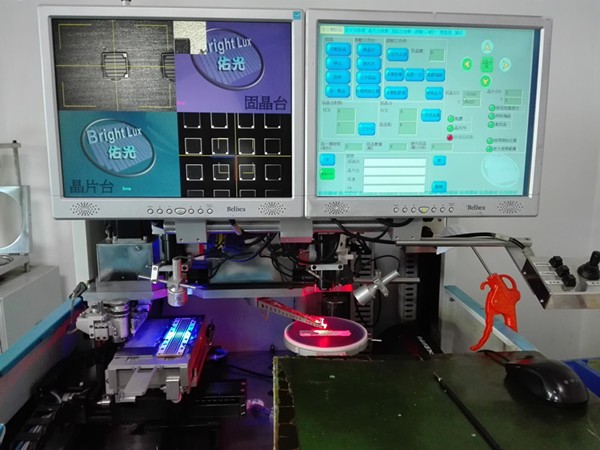

Our UVLED unit use chip assembly instead of lamp, it makes our products efficient and high intensity with a small form-factor.

Quartz package

Our UVLED system use quartz for encapsulation chips. It is anti-radiation, high temperature resistance, easy maintenance and have a lower cost.

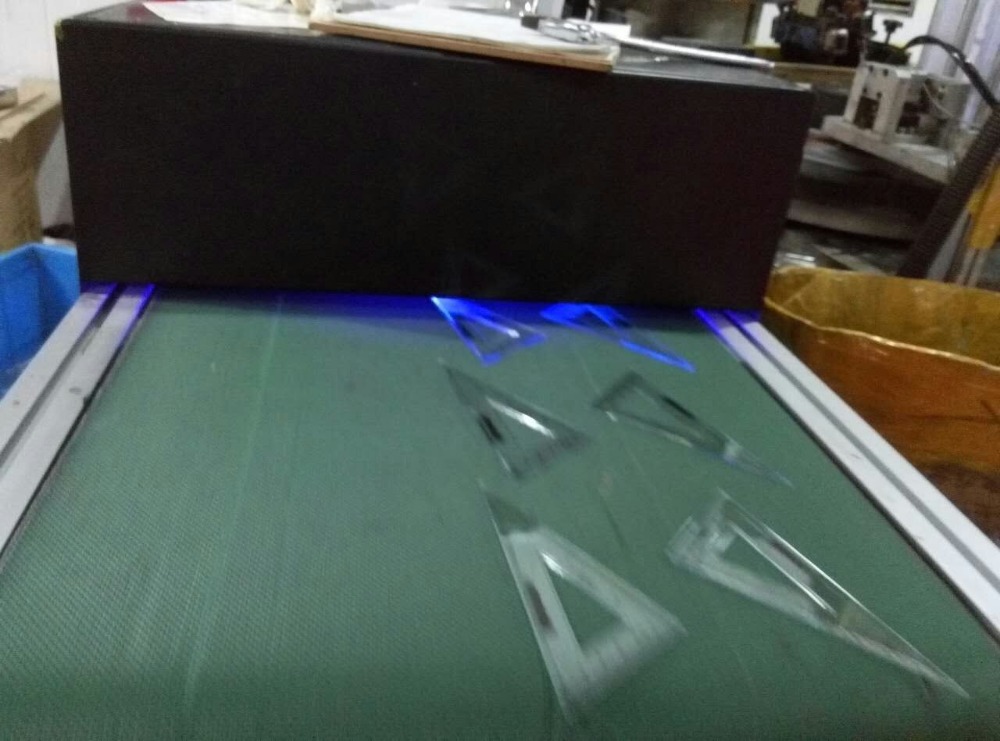

The UV curing system is suit for Ceramic Labeling, glass surface printing, bottle printing etc.

It increasing productivity, reducing cost, and decreasing their impact on the environment

It also allows for printing on heat-sensitive substrates and ever-thinner labels.

RWUVLED enabling end users to print high quality material at maximum speeds.

higher productivity,

lower enrgy usage,

reduced heat load for thinner substrates,

smaller footprints

clear environmental benefits

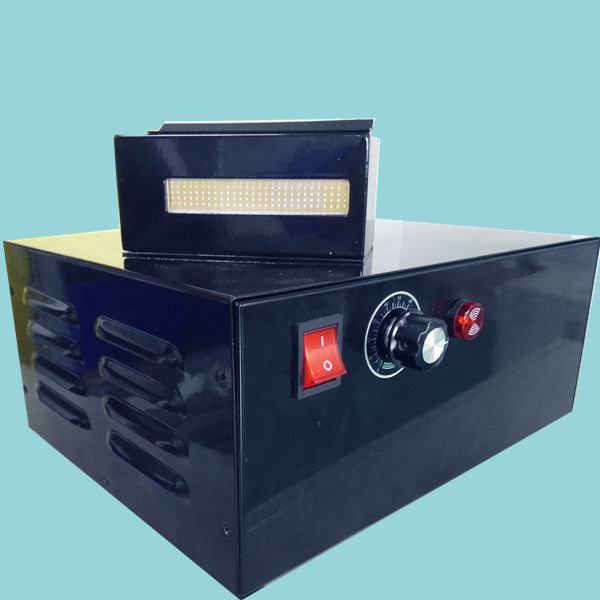

Small form factor

High peak irradiance

Custom sizes available for longer curing lengths

Ideal for narrow & wide web curing

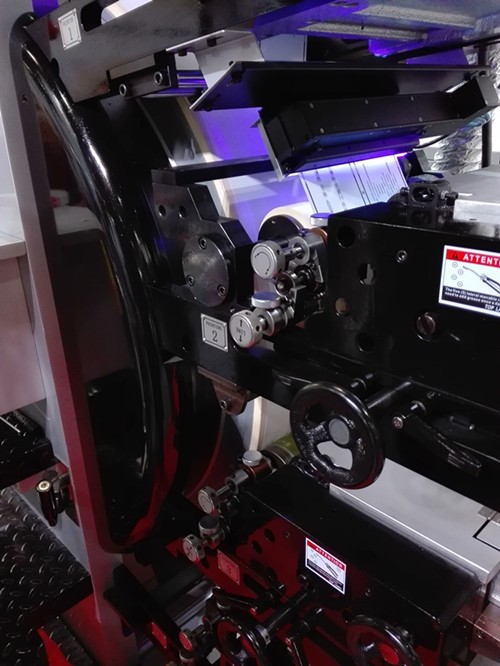

All water-cooled systems are designed to be rugged and reliable to succeed in the toughest customer environments.

Simple integration

No external cooling required

Low operating cost

Scalability

All air-cooled systems are designed to be versatile and can be used for high performance curing, pinning, and small area curing.

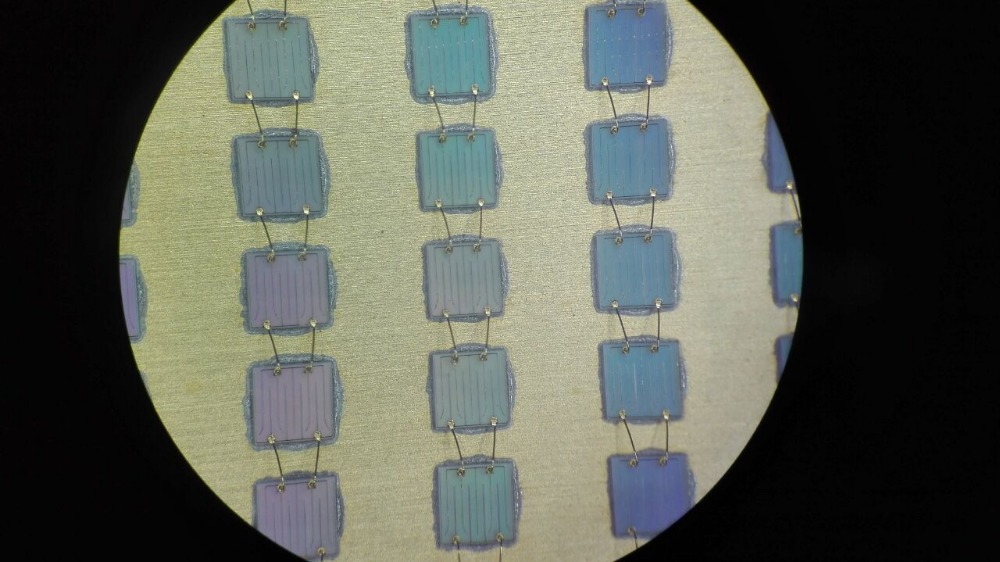

UV LED for Adhesive

Electronics ( TOuch Panel, Mobile Phone, Micro Speakers, Disk Drives and etc)

Medical

Industrial

UV Coating LED curing machine

Wood products( Edge coating and Roller coating)

Automotive

Industrial

UV ink LED curing system for Printing

Digital printing( Labels,bottle, 3D, Coding,Poster and etc)

Screen printing

Flexo and Narrow web printing

Advantages of LED UV curing system instead of the mercury lamp.

• Uniform radiation of the lamps across the entire working width.

• Clearly reduced exposure to noise of the line operators since no exhaust system is necessary.

• Stepless adjustment of the specific lamp power from 20 - 100 %.

• Instant on/off without waiting times.

• No waste disposal of old UV lamps containing heavy metal (GA, Hg).

• No exposure to ozone of the line operators.

• Excellent penetration of the UV radiation allowing for good adhesion, also with pigmented lacquers.

• Less danger of uncured photo initiators.

• Reduced risk of fire on UV lines, possibly reduced insurance premium.

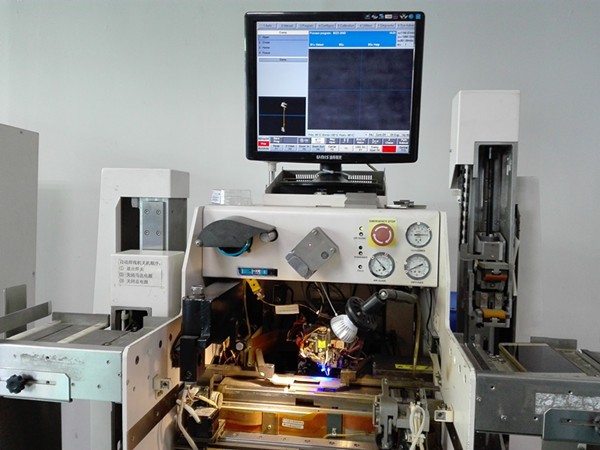

Established in 2010, Shenzhen RenWei optoelectric Co., Ltd is a professional manufacturer and exporter that is concerned with design, development and production of LED UV curing system. We located in Shenzhen city, nearby the Hongkong airport and Shenzhen Baoan airport.

Covering an area of 700 square meters, we now have over 30 employees, boast an anunual sales figure that exceeds USD 5000,000. And currently export our products worldwild.

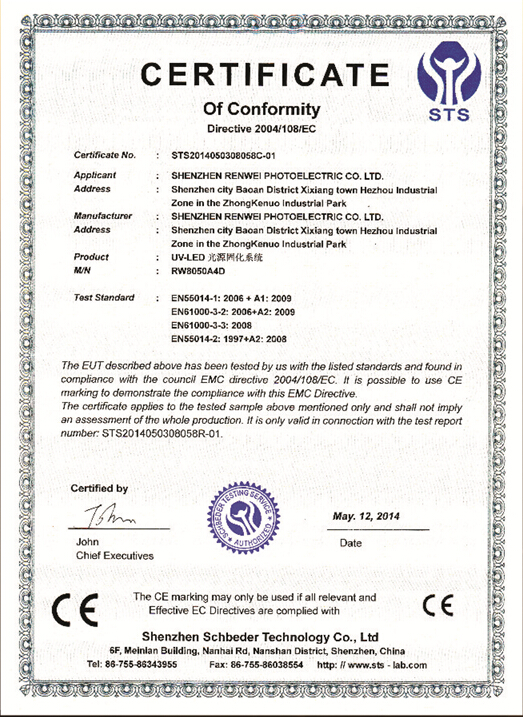

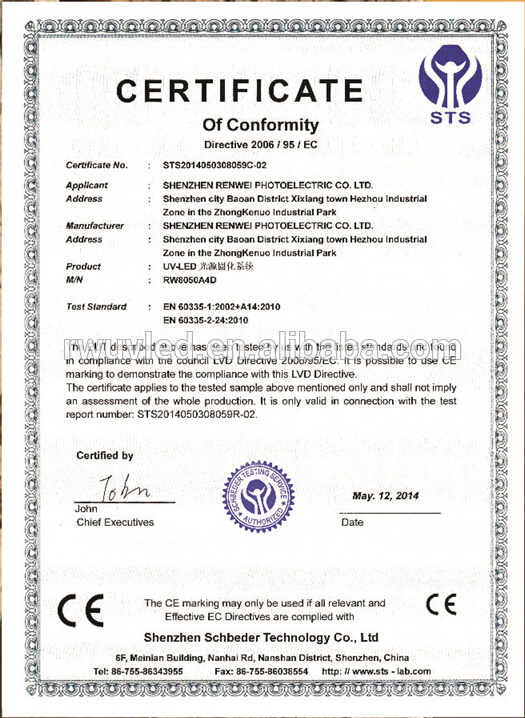

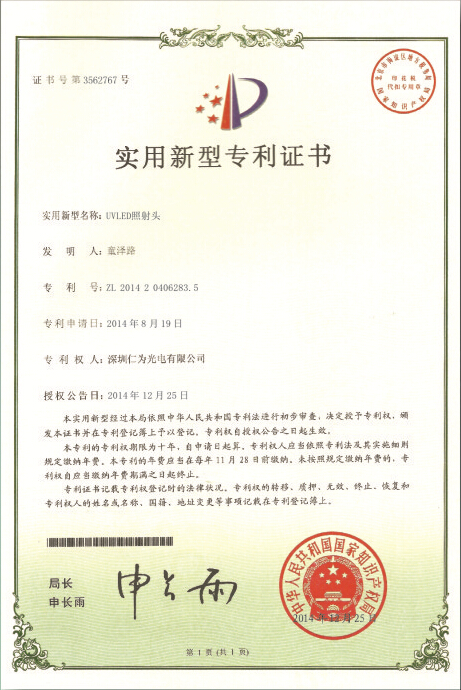

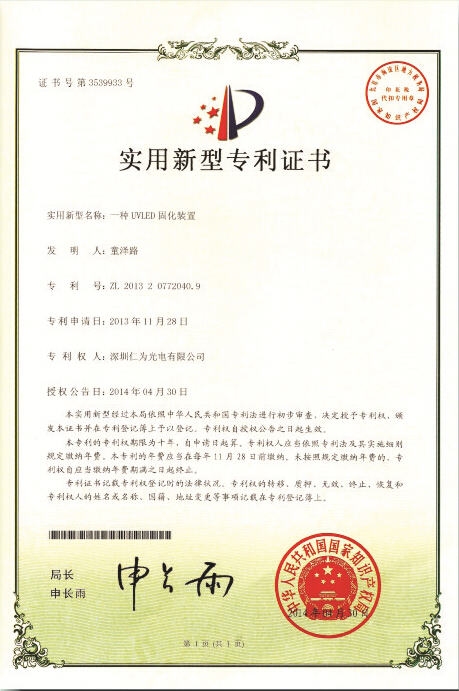

Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. Besides, we have received 8 patents and 4 CE certificates.

As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching North America, North East, Asia, European.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

A: RenWei optoelectronic products have the following advantages when compared with other companies' products

1.Chip on Board, high-energy and high efficient.

2. Directly cooling, with out heat sink, better heat dissipation, smaller light fades , longer working life.A:UV LED's working time is more than 20,000 hours, 10 times longer than the traditional lamp, Besides, UV LED curing is effective, energy saving and environment friendly.

A: No, The coatings/inks must be specifically to take advantage of the narrow Wavelength, Ask for your supplier for the best wavelength, we can customized the UVLED's Wavelength.

A: Yes, The coatings/inks suppliers have solved this problem to ensure the same performance.

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

A: No. UV LED System can be turned on/off instantly.